Project description

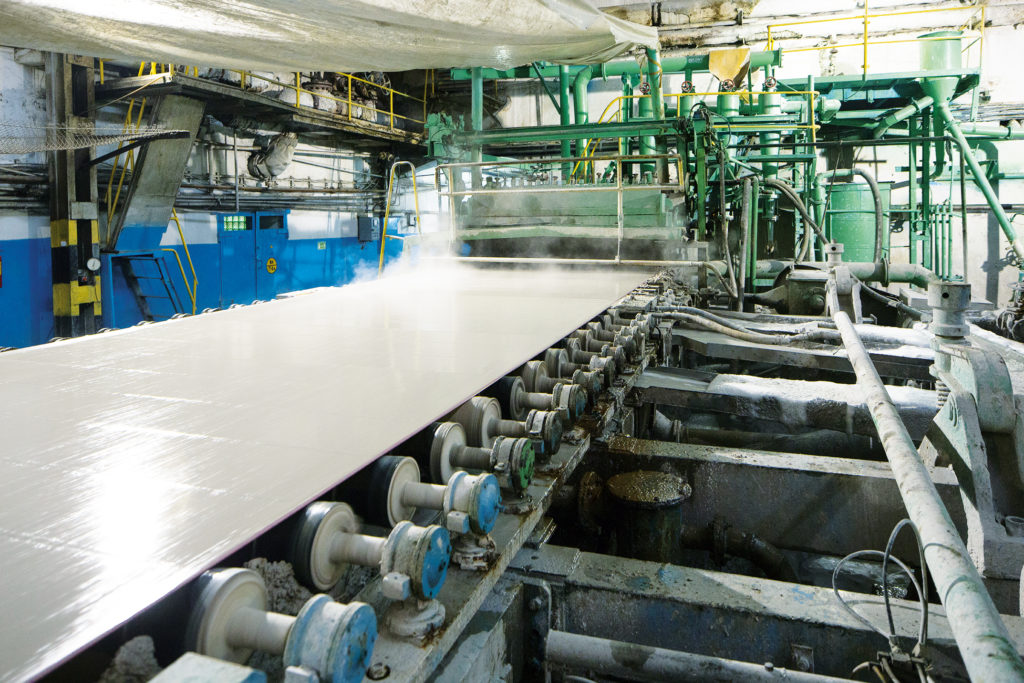

The Koehler Group previously consumed about 62.000 metric tonnes of coal annually, sourced from South Africa and Colombia. This fossil fuel had to be shipped halfway around the world, resulting in about 150.000 metric tonnes of direct CO2 emissions per year. Since its founding in 1807, Koehler has relied on renewable energy (hydropower). Through Koehler Renewable Energy for biomass expertise and Koehler Innovation and Technology for engineering, the company is switching from fossil fuels to regional biomass.

To support this, the Koehler Group has invested over 70 million euros in the Oberkirch mill.

The implemented solution

The existing power plant, built in 1986, underwent several significant conversions to accommodate the new fuel. This included the construction of two collection points for unloading trucks and corresponding silos. The fuel mix includes wood chips, biogenic waste, and residues from wood processing. One advantage of using such carbon-neutral biomass is its availability in the region.

By converting the power plant to biomass, Koehler will reduce direct emissions by over 150.000 metric tonnes of CO2 per year at the Oberkirch site, advancing both its carbon-neutrality goal and Germany’s national climate targets. The Koehler Group will continue to reduce its carbon footprint through efficiency improvement processes, one step at a time, as set out in its environmental and climate action strategy.

The key hurdles solved

Pre-project feasibility studies, permitting and ensuring a reliable regional biofuel supply were key steps in the construction and upgrade of the power plant.

Key Suppliers / Partners

- Koehler Innovation & Technology

- Valmet