Project Description

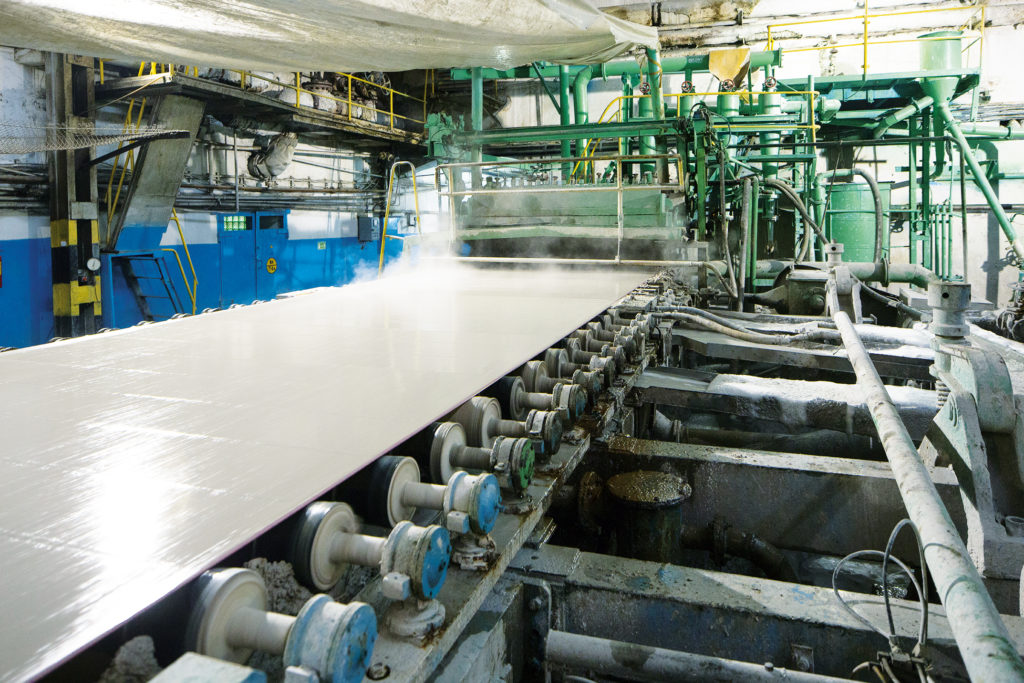

To provide heat as a source of energy for paper mill activities, the project aimed at implementing a 3.7km steam network pipe between Cartonnerie Gondardennes (CG) and Flamoval municipal solid waste incinerator (MSW) located nearby. CG supplies demineralized water to the MSW, which sends back vapor steam heated at 235°C, 15 bar for the drying of the paper and cardboard production.

Heating network process

What was innovative at the time is the investment in a network to transport steam over a long distance with almost no heat loss. Decarbonation of the paper mill activities was the main driver of the project.

The main stakeholders were:

- Cartonnerie Gondardennes paper mill;

- The Municipal union (so called Syndicat Mixte Flandre Morinie) managing the incinerator;

- Municipalities’ association (so called CAPSO), local authorities and landowners (VNF, SNCF).

This steam network project was a public-private partnership with technical, administrative and economic challenges, notably:

- A steam network pipe crossing a canal river;

- A lack of visibility about energy savings (at a time when gas was largely affordable);

- Project financing (notably FEDER European regional development funding);

- Risks sharing between paper mill and the incinerator.

External promotion: information sessions open to the public (town hall), incinerator was not well accepted initially, but the synergies with a key local company as CG was seen as a guarantee.

Project Purpose

For CG, the objectives were:

– The decarbonation of recycled paper production aligned with the Corporate Social Responsibility commitments;

– The resilience of industrial activities (by reducing dependence on fossil fuels);

– The competitiveness of steam production.

Result: more than 24.000 tons of CO2 saved in 2022 by reducing gas consumption.

Project Evaluation (2.3)

Discussion between the paper mill and the Municipal union were initiated since 2012. It took 10 years to develop the project and 2022 was the first year of operation of the steam pipe network. This project allowed a reduction of 24 ktons of CO2 and secured paper mill steam production, while limiting exposure to natural gas market price volatility. Total investments for the project were 13.85 M€. Further developments aim at developing a continuous heat supply over a 12-month period (instead of a 7 months period) in 2028 and beyond, to reduce paper mill CO2 emissions by 14 ktons of CO2. Such project is viable, profitable and replicable for any paper mill located nearby an incinerator.