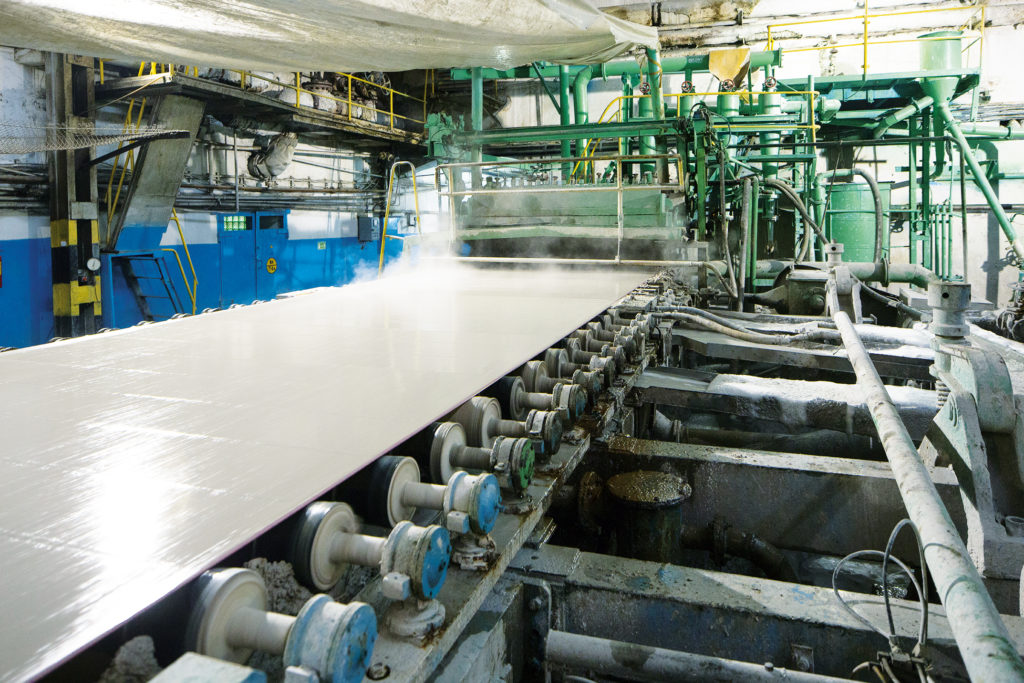

Project Description

Norske Skog is investing €72 million in a new waste-to- energy boiler at its paper mill in Bruck (Austria).The new boiler will replace the steam production of existing natural- gas-fired boilers used for paper operations, reducing fossil CO2 emissions by about 150,000 tonnes per year. In addition to supplying heat to the paper mill, the boiler will also provide steam to the district heating network in the city of Bruck. With an annual capacity of 160,000 tonnes of waste, the boiler will meet the increasing incineration demand within the EU and Austria for refusederived fuels (RDF) and sludge, and reduce the amount of material going to landfill.

Project Purpose

The boiler increases Norske Skog Bruck’s longterm competitiveness through energy saving, reduces its carbon footprint and diversifies its revenues by generating revenue from the combustion of RDF, rejects and sludge from the Austrian pulp & paper industry.

The boiler will provide Norske Skog Bruck’s industrial operations with cost-efficient and sustainable steam, and is an important stepping stone for further strategic and green investments at the Bruck site.

Project Evaluation

The investment decision of €72 million for the waste-to-energy boiler was taken by Norske Skog in June 2019. Construction of the boiler and related infrastructure are currently ongoing, all on budget, with start-up planned for the first half of 2022. The boiler operations will have a strong regional sourcing concept, with around 90% of RDF and sludge being sourced within 200km