Project description

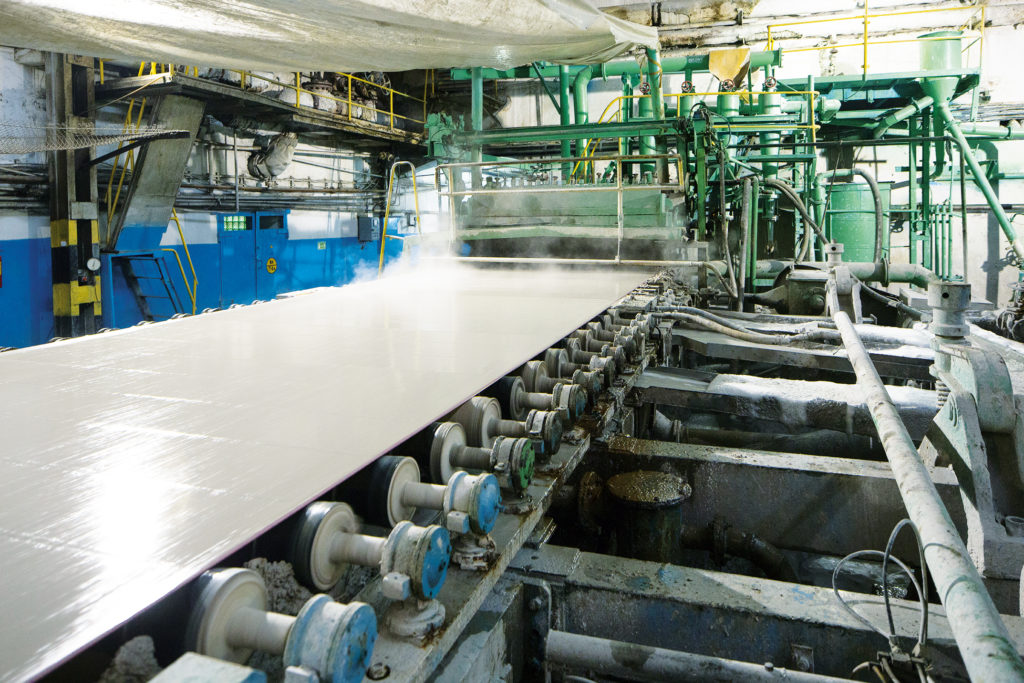

Paper production is energy-intensive, requiring large amounts of gas to generate steam for drying. The steam recovery project launched at Essity’s plant in Gien delivers steam from a municipal incinerator 3.5 km away, which burns waste from the facility as well as local household waste.

The main challenge was to convince the management to commit to a longterm energy supply contract (13 years of supply, beyond the two years required for implementation and commissioning); the commercial terms had to ensure returns for the investor (the Public Service Delegate).

Project purpose

The goal is to reduce Essity’s dependence on fossil fuels. The company set up the project together with two external stakeholders: Paprec Energies, part of the leading French recycling company; and SYCTOM, an association of local governments. It covers at least 70% of Essity’s steam needs. Because the factory needs steam year-round, Paprec Energies is able to satisfy regulatory requirements for the generator that it couldn’t meet if it only supplied a district heating network, with seasonal demand. The project helps mitigate increases in household waste processing fees.

Project evaluation

The project has cut the Essity plant’s gas consumption by 87 GWh, reducing direct CO2 emissions by 16,000 tonnes. The Essity plant is the largest gas consumer in the Loiret Department, so the project will make a significant contribution to meeting the government’s plan, announced in October 2022, to cut energy consumption by 10% by 2024. Recent increases in European gas prices mean the economic benefits are far greater than was expected when it was set up three years ago.

What is exceptional about the project?

It won a subsidy from the National Environmental Agency (ADEME). It ensures a competitive steam cost for Essity long-term.

Can this project be a model for the future?

Other Essity facilities aren’t close enough to potential incineration assets, but it clearly demonstrates an opportunity for other industrials.

Is the project part of a bigger decarbonisation scheme?

Essity’s journey to net zero includes low-carbon raw materials and fossil-free production. We have been pioneering accelerated innovation on reusable products and designing to reduce consumption. Other projects include recycling paper and packaging, and installation of biomass boilers.