New generation bioproduct mill

Project Description

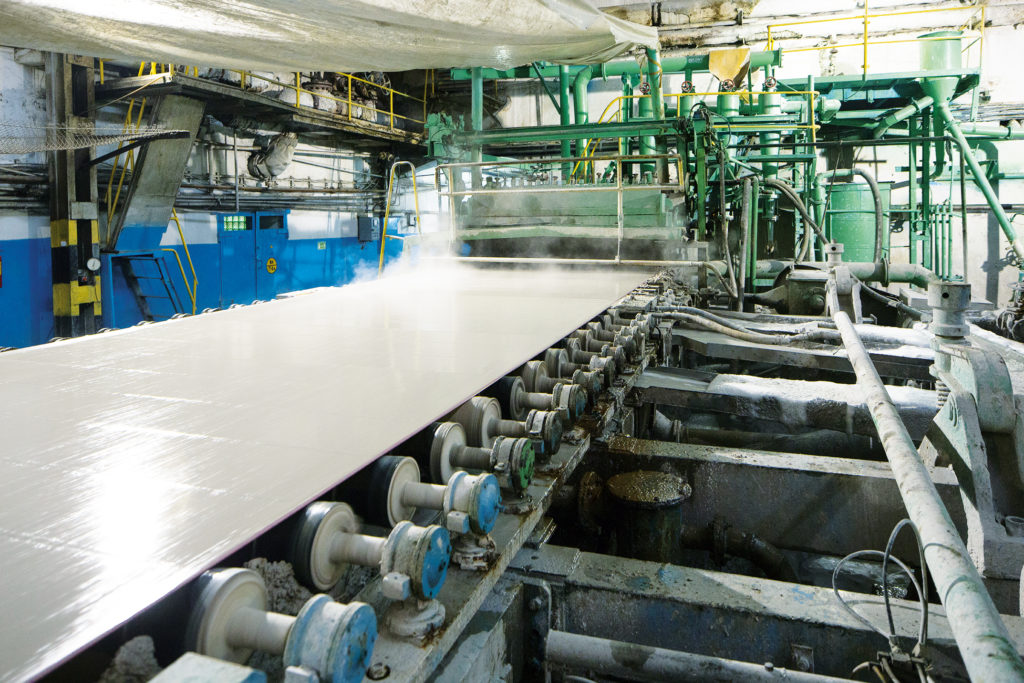

Metsä Group built the first next-generation bioproduct mill in Äänekoski, Finland – the largest investment of the European forest industry with a value of €1.2 billion. The new mill, starting in the third quarter of 2017, leads the industry to a new era of resource efficiency through operating with no fossil fuels and fossil CO2 emissions, being the most energy-efficient pulp mill in the world and utilising 100% of the production side streams in an industrial ecosystem built with partners.

The new mill generates 2.4 times the amount of renewable electricity it consumes. It increases the renewable energy production in Finland by 2 percentage points. The mill also produces a large variety of biomaterials and biochemicals.

The mill is a flagship project of a resource-wise bioeconomy and circular economy, using both the raw material and the production side streams efficiently. For example, the sludge from the process is used for biogas production by our partner EcoEnergy SF to replace fossil fuels in traffic and industry. Another circular economy solution implemented at the mill is capturing sulphur emissions and converting them back to sulphuric acid for the process of the mill.

Project Purpose

This major investment brings more than 2,500 jobs throughout the value chain in Finland, including 1,500 new jobs. It increases the value of exports by around €500 million per year. The new mill will also diversify the structure of the Finnish forest economy and bioeconomy by introducing new bioproducts with high value added.

Project Evaluation

The bioproduct mill uses no fossil fuels and causes no fossil CO2 emissions. It only uses wood-based biofuels, generated mainly from its production side streams. The mill is a significant producer of renewable energy.

The production side streams will be utilised for higher added value products within the globally unique industrial ecosystem.

The new technologies of the bioproduct mill can be implemented at other mills. Taking into account growing global consumption, it is obvious that more resource-efficient solutions are needed, paving the way to a circular economy.

All the wood arriving at the mill comes from sustainably-managed forests, mainly in Finland.

Ismo Nousiainen

Senior Vice President

Production, Metsä Fibre (CEO of Metsä Fibre as of 1 January 2018)

“We have created the first next-generation bioproduct mill concept that takes resource efficiency to a totally new level. Our environmental performance has clearly improved: pulp production is 2.5 times higher than before, but the environmental impact remains at the former level. The new recovery boiler is the most energy-efficient in the world; we produce 2.4 times the amount of electricity that the mill consumes. We deliver significant amounts of energy to the grid, representing 2.5% of Finnish electricity production. The mill is completely fossil free as we use only biofuels. We utilise 100% of the side streams to produce a wide range of bioproducts within the industrial ecosystem by the site.”