Project Description

What makes your project innovative relatively to decarbonisation? Who are your stakeholders and how were they involved? What challenges did you face and overcome along the way? Did you promote the project internally and externally?

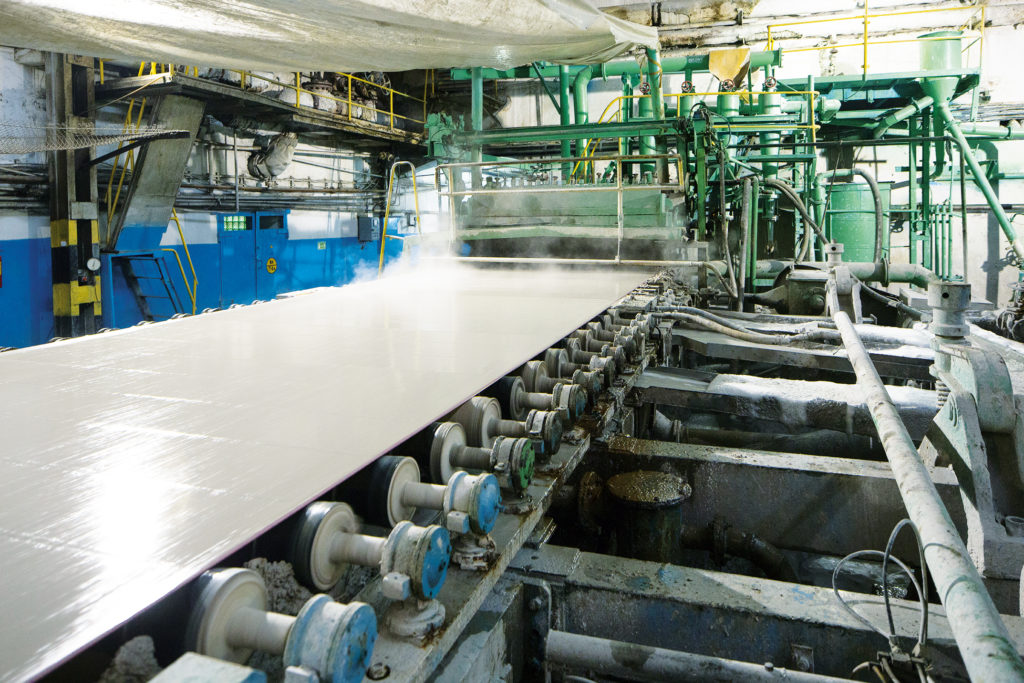

Metsä Group’s implanted a state-of-the-art sawmill in Rauma, Finland. The sawmill is operating in three shifts and started end of September 2022. The sawmill is a worldwide frontrunner in technology, efficiency and operating models and responds to the demand for high-quality, sustainably produced sawn timber. It relies on technological innovations such as machine vision, self-learning AI and integrated information systems that control the site’s various functions.

Sawn timber is a sustainable product that can help us achieve our collective decarbonisation goals by storing the carbon contained in trees in products throughout their life cycle. The sustainability of the sawn timber we produce is based on sustainably managed forests, certified and traceable wood raw material and low-carbon production.

Project Purpose

Provide a clear, concise statement of the project’s reason and intended results. Who or what has it benefited?

The pine sawmill increases forests value, it enables fossil free production and increases the production of products that store carbon for a long time.

The Rauma sawmill is three time faster than a conventional sawmill. The maximum sawing speed will be 250 metres per minute. A pine log is sawn into sawn timber products in just over a second. The logs are sawn with careful optimisation.

Rauma has a pioneering approach with its single central control room. In practice, this means that sawn timber passes through the processing line without manual work stages.

A responsible supply chain and data collection will ensure that our customers have access to first-class strong Nordic pine sawn timber. The wood we use is traceable.

Project Evaluation

These statements should be consistent with the project purpose and provide measurable project outcomes. What are the main measurable, qualitative and quantitative achievements? How cost effective was your project? How do you measure it? Where do the savings occur? What are the project follow-ups? Could your project be reproduced in other regions or countries?

Rauma sawmill boasts state-of-the-art technology and unparalleled efficiency. As the most advanced sawmill in the world and Finland’s largest-ever sawmill investment, it has created benefits for the entire sawmill industry.